Products

Maha clean(Purging Material)

Very suitable for the Cleaning of Extruder and Injection Machine

Maha clean is a purging material for Extruder and Injection Machine. Maha clean is mainly characterized by high heat resistance and high detergency.Therefore, it can be used with engineering plastics and super engineering plastics(except POM) in High and Wide Temperature Range (Polycarbonate base is 220℃~360℃,S-01 can be used at temperatures above 360°C) In addition, because it does not use hazardous there is low extruder contamination,and it contributes to a good Operation Circumstance since it does not generate any odor.

Maha Clean has the following lineup depending on the application.

①P-500 and P-100 (filler types)

This series can get the smooth Cleaning Work and ideal for purging Flame retardant plastic in extruders and injection molding machines.

②P-36(non-filler types)

P-36 is contain AS resin in addition to PC resin.This series can get the good resin transparency for the High Purging Property.

③P-55(non-filler types)

This Grade is including PO resin in addition to AS resin.P-55 is inferior in replaceability to P-36, but has high cleaning ability.

④S-01

S-01 is a purging material for super engineering plastics, and is this grade that can be used in the range of 320℃~370℃+α(here is also a track record of use at temperatures above 400°C. Please contact us for more information.)

- High Cleaning Power

Very suitable for the Cleaning of Extruder and Injection Machine after Products of Engineering Plastics Flame Retardant Grade - High heat resistance

Polycarbonate base Grade can be used in a wide temperature range of 220°C to 360°C. And,S-01 can also be used in the temperature range of super engineering plastics.Maha Clean have High Heat Resistant because of Raw Materials with high heat resistance. - Low Contamination and odor

Not use hazardous Materials,and the degree of contamination is low. And, keep the good Operation Circumstance by Low odor. - Can get the smooth and short Cleaning Work

Good Handling for Disassembly and Cleaning Work.(P-100, P-500, P-55 are best). - Can get Low Dust Products

Removes contamination with strong cleaning power and reduces product defects.

Temperature Range(P-500 is best).

Temperature Range

Polycarbonate base Grade can be used in a wide temperature range of 220°C to 360°C. And,S-01 can also be used in the temperature range of super engineering plastics.Usable temperatures for Mahaclean are as follows.Maha clean can be used with all most engineering,super engineering plastics.

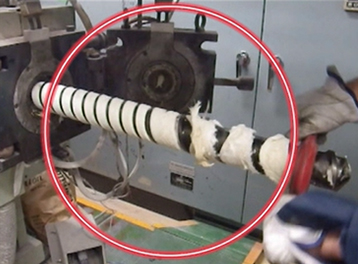

Comparison example with another company’s purging material

P-500 Extruder Evaluation (for Br flame retardant red PC)

| Using Company A’s purging material | Using Maha Clean P-500 |

|---|---|

| The other company’s purging material has fewer swells than ours, and char. | Maha Clean is very good swelling |

|

|

| Styrene-based purge material is Sticky and hard to pull out. | No carbonization and Easy to pull out. |

|

|

| Hard to peel off. | Easy to peel off. |

|

|

*P-55 and P-100 have the same workability and replaceability as P-500.

P-500 Injection molding evaluation (PPS GF30% BK color)

Comparison results

In purging test, P-500 replaced PPS after 3 shots. However,Competitor's products were not able to replace PPS. This confirms the excellent replacement and cleaning ability of P-500.

Injection molding evaluation (P-36 with other companies' products)

Evaluation method

- Injection molding of Red color PC (500g).

- After molding, cleaning material (500g) used for cleaning.

- After ejecting 3shots, take 20shot molded products

with PC resin and evaluate the appearance

The image above is No1, 5, 10, 15, and 20 shot plates are stacked from the top,

and the LED light source illuminates from the bottom.

Evaluation results

| Odor, gas strength * Company A Company B are extremely bigger. |

Company A> Company B> Company C> Maha Clean P-36 |

|---|---|

| Superiority or inferiority of the cleaning material. | P-36 = Company B≧ Company C> Company A |

*This test shows good replacement performance. However,B has a fast MFR and may not be suitable for all applications.

*P-36 is a grade that is excellent for replacing non-filler types. It has better cleaning properties and lower odor than comparable products.

Injection molding: S-01 PEI purging evaluation

Evaluation method

Use 500g of red PEI and 500g of cleaning agent after molding.

After that, run PEI NAT and evaluate when the replacement is completed visually and by weight.

Evaluation results

Amount of each purge material required to clean the red PEI was 409g for S-01 and over 900g for PC-GF type.

Amount required for replacement was 113g for S-01 and 203g for PC-GF type.

S-01 has excellent cleaning and replacement performance.

| Molding machine name | FANUC ROBOSHOT S-2000i50A (50t class) |

|---|---|

| Cylinder temperature | 360℃ |

Product Specifications

Grade Line-Up